Automated Defect Inspection System with Robotic Arm and Deep Learning

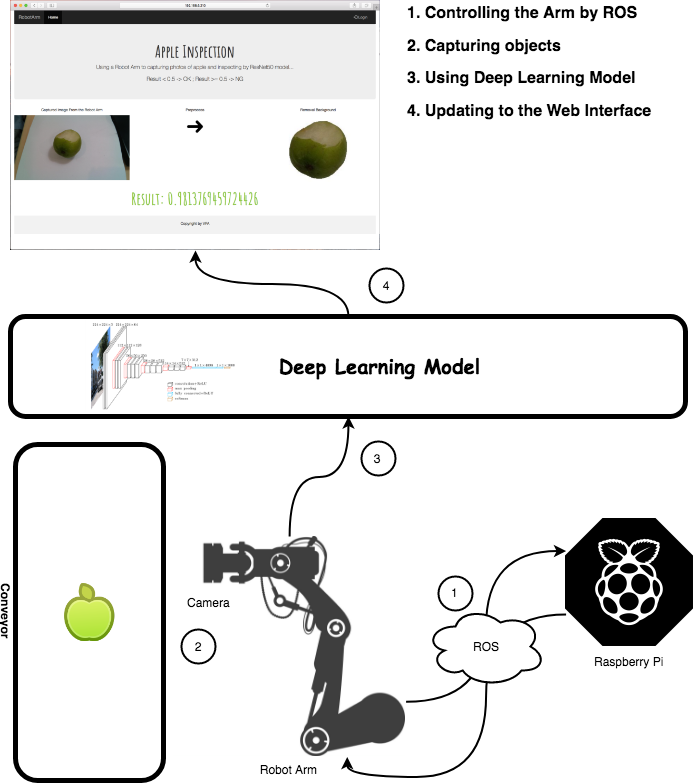

Developed an automated defect inspection system to efficiently detect and classify product defects on a conveyor belt.

Automated Defect Inspection System with Robotic Arm and Deep Learning

Github: https://github.com/quocnh/Automated-Defect-Inspection-System-Using-Robotic-Arm-and-DeepLearning/blob/master/Publication.md

Dashboard Visualization

- Designed and implemented a robotic arm system for real-time product defect inspection on conveyor belts, integrating ROS for motion control and automation.

- Developed an efficient C++ program to automate object data collection, leveraging computer vision techniques to extract high-quality image frames from video streams.

- Built and optimized a deep learning model using ResNet-50, achieving high accuracy in defect detection by training on customized datasets with precise annotations.

- Streamlined the pipeline for real-time defect identification and decision-making, demonstrating expertise in combining machine learning and hardware optimization.

Video link:

- https://drive.google.com/file/d/1KCF31cqWTbForki-6d7YNfTgb_rOv_WZ/view?usp=sharing

- https://drive.google.com/file/d/1sIMJ3BOCjd-B2ghHndZeDxoD2xsCqL9v/view?usp=sharing